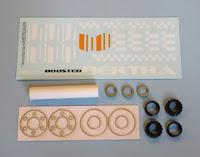

There are a lot of centering rings with all the motor mount adapters.

I usually sand off the laser cut burn marks from the flat faces of the centering rings.

The ring diameters are just slightly big and will require some sanding for a friction fit over and inside the tubes.

Note the tubes have the words "AFT" and MID" burned into them.

Test fit all the rings on the tubes before sanding the edges. All my supplied rings were a little too tight.

I prefer rings that are cut a bit large so you can sand to a perfect fit.

After the t-nut is in place, epoxy glue is set around the outside edges of the nut.