I simply glued the lower engine block in the bottom, even with the end of the BT-5 tube without using the yellow tubes..

With the lower engine block glued into the bottom of the booster stage -

With the lower engine block glued into the bottom of the booster stage -

Slide in the two taped together yellow spacer tubes into the booster stage. Slide the upper stage body down on the top half of the taped yellow tubes.

The upper engine block is slid down from the top until it butts up against the yellow spacer tube. I applied a glue fillet around the top joint.

Both the top and bottom lugs are glued towards the top leading edge of the adjacent fin.

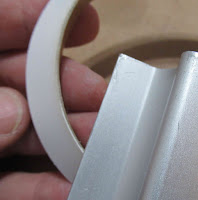

Here's a step that isn't really needed, but I did it anyway hoping for a smoother final finish.

Some CWF filler was directed into the joint seams with the tip of a dull knife blade. After it dried, the bottom was sanded with 400 grit.

One shot of filler/primer and sanding followed, filling any remaining seams.