Mentioned earlier -

This is a large model, hard to get even coverage using a spray can. Spray it in sections.

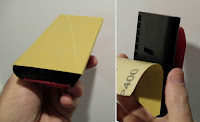

Here's the 4" diameter lower body. Look to the low end cutouts. There is masking tape, sticky side out, to keep paint out of the engine mount area. There is also tape inside the open top end of the tube.

Normally I'd use a painting wand (a dowel with an engine casing glued on) to paint, but this model is too large for that.

My free hand can go inside the tube on either side to hold the body while spraying.

TIP: Place a plastic grocery bag over your free hand to keep off the paint.

TIP: While the instructions say to paint the model with flat white, I'd recommend a

gloss white. You'll be handling this model a lot when masking for the black. Flat paint is a dirt and finger oil magnet. Gloss paint can be cleaned if needed.

Also - Decals stick better on a smooth, glossy surface. Decals will "silver" on flat paint. The clear coat border (over all decals) will be seen.

You can always spray a flat clear coat after the model has decals and is finished.

To the left: The shoulder of the Command Module was masked off. A piece of rolled card stock gave me something to hold on to.

Notice the escape motor tube was already seam filled, primed and sanded.

In this new version, the 3rd Stage Wrap totally covers the 3rd stage tube.

TIP: Allow more time before re-coating the white on the 3rd stage wrap. Sprayed on the flat plastic, the paint can't breathe and dry like paint would on a Kraft body tube - from the outside and inside.

I thought I gave it enough time but had three small areas wrinkle up! This slowed down the build as it had to be sanded, sprayed with filler/primer, sanded and sprayed again with the white.

Spray some white, let dry and sand down any glue boogers or rough areas. Spray more white.

On the left is the final (gloss) white before the time consuming black masks.

Assembly time so far:

21:00 minutes previous

2:30 minutes this post

23:30 Total so far