On YORF, Jeffy Jeep mentioned he didn't care for the Starship Excalibur name font used on the Semroc decal sheet. I had to agree!

You have to realize this model was designed back in 1968! An amazing design for that time. In 1968, font choices were few. New fonts were expensive and print shops used what they had on hand.

I wondered why Carl at Semroc picked this font for the kit. Look at the upper right of the Estes plan shown above - there it is! Carl was just following the Estes example.

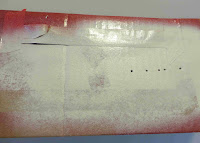

The original font looks to be set in Dom Casual Extra Bold, a goofy looking font for a Starship. I looked through some type styles that were already on my laptop.

#1 is a good choice. Bold, contemporary and easy to read.

#2 is the same font used on the Star Trek Enterprise.

#3 is too modern and doesn't reflect the year this model was designed. The "S" is a little like Star Trek logo.

#4 reminds me of Battlestar Galactica or Intellivison.

#5 just doesn't work - too bold and too recent.

Type fonts should reflect the design and the time period of the subject.

I'll want to pick a font that was from around 1968 but maybe not available for sale then.

I'll probably go with #1 or #2,

What do you guys think?