They haven't been produced since Hobbico went out of business.

Apogee Components saw a need and filled it -

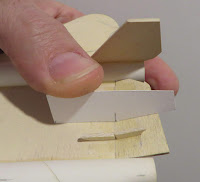

Apogee Components saw a need and filled it -This is their new 11" long Sanding Tee.

To see it: CLICK HERE

You can hold a piece of folded sandpaper around the sides with your fingers while sanding. I find I have more control using some sticky back sandpaper, you can certainly use that here. With adhesive backed sandpaper you can concentrate on sanding instead of trying to keep the sandpaper tight and still.

Apogee added a rounded side, Tim says it is for sanding fillets. You've got to be careful sanding over a hard edge like this. You can easily sand into the balsa fin.

This new Sanding Tee is sold in an 11" length.

My two Great Planes sanding blocks are both 5.5" long, a perfect size for me. If I were to buy an Apogee Sanding Tee, I'd probably cut it in half and have two blocks with different grades of sticky backed sandpaper on each.

This looks to be an essential addition to any work bench.