The kit supplies some pre-cut black vinyl trim strips.

When applied on the model the black and white paint pattern reminds me of the Wac Corporal.

The black trim is 1/4" tall. Get an idea of the spacing by setting the strip with 1/4" of the white showing.

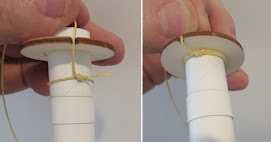

The instructions wisely suggest wrapping a strip of paper around the tube for an alignment guide.

Don't peel all of the backing off initially -

peel back an inch or so, apply and repeat.

Notice the pencil mark. That's the stop and start point directly over the launch lug. I started the strip with a slight overlap in mind so the left end is placed to the side of the pencil mark.

With the rocket on the launcher and the launch rod in the back, any misalignment of the wrap won't be seen when taking pre-launch pictures.

Here's a better look of the alignment paper and the start (center) of the tape strip.

There is a third wrap strip at the top of the body tube.