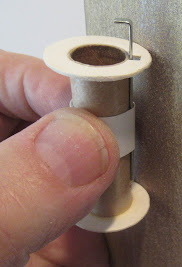

It was pressed in dry using an engine casing.

On the right -

While the instructions might tell you to run a line of glue around the tube and slide the ring in -

Add the glue fillet after the ring is slid in place.

I set the rear ring even. The upper ring was set about 1/8" lower than the tube end to allow for glue fillets on both sides of the ring.

The fit was tight in the BT-50 main airframe tube.

Both rings were sanded to get the diameters slightly smaller.

Go easy and check, it doesn't take much sanding to get a friction fit.

This is giving me all kinds of feels. I bought mine at KayBee Toy & Hobby in the summer of 1977. I can remember building it on the ping pong table in the basement. Unlike most of my other builds, we happened to have white and red paint handy, so I could pull off the catalog paint scheme. I thought the finished product was the coolest thing I'd ever seen.

ReplyDelete