* Chris Gonnerman commented on the Alpha II:

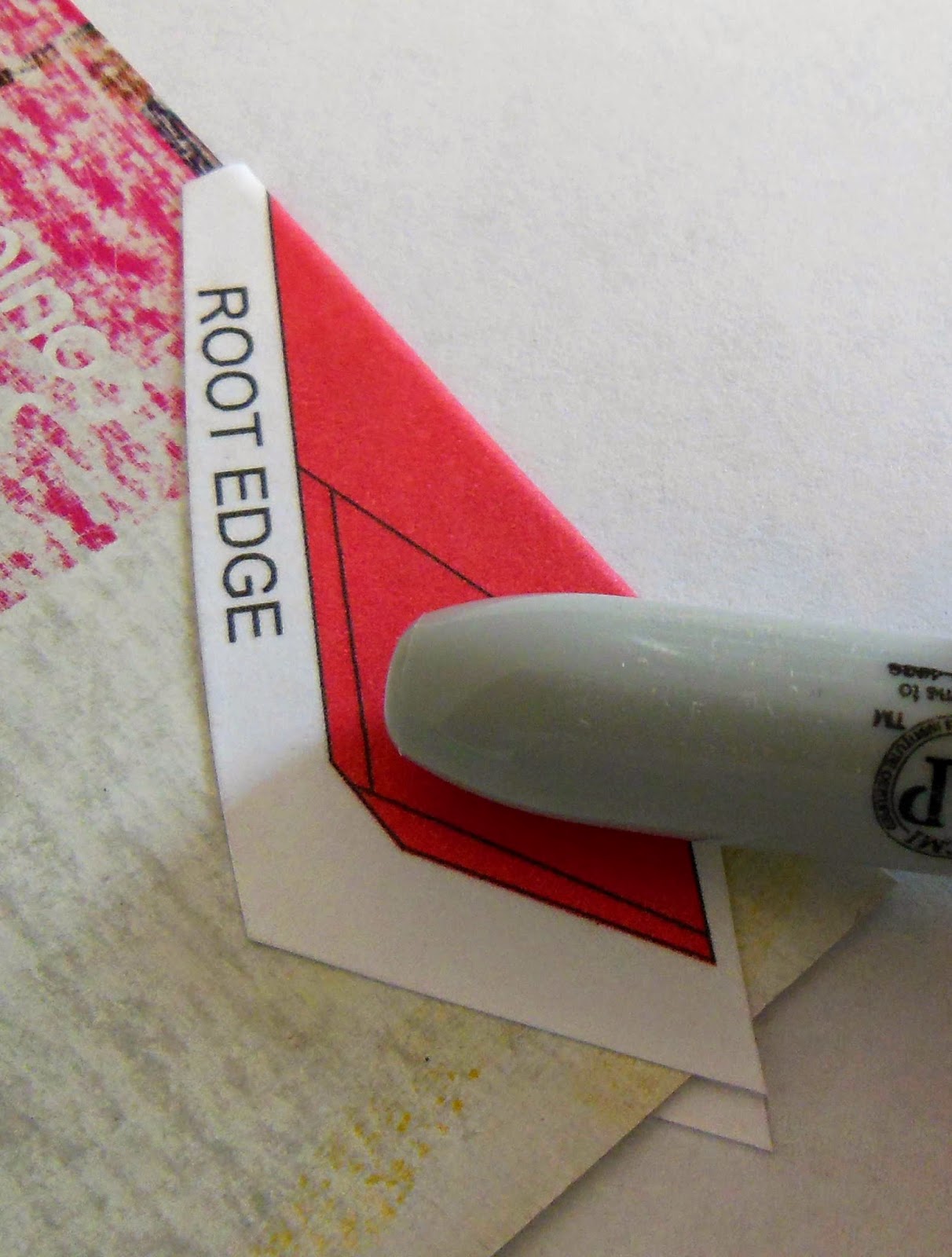

"According to CPMcGraw and BEC on YORF, the Alpha II was an educator-only kit; it had either a balsa or plastic nose cone, fins with the root edge marked by the die cutter, and an extended engine mount to which you attached the shock cord."

* Bernard Cawley posted the Alpha II instruction PDF . . . You can see it HERE

* Lonnie Buchanon commented:

"The Alpha II was an identical kit to the Alpha, except that it had a plastic nose cone instead of balsa."

I found the instructions interesting.

In the Alpha II instructions the elastic shock cord is tied underneath the top bend of the engine hook.

I had never seen this method used before in an Estes kit. Personally I wouldn't want an elastic cord this close to an ejection charge. The rubber would decay very quickly.

This is the same method used in many Semroc kits, except the lower end of the shock cord is flame resistant Kevlar and not rubber.

I wonder if the Alpha II was the inspiration behind the Semroc style Kevlar tie?