The instructions don't mention it, but I'm going to round the edges on the presentation model.

I drew a pencil line for reference all the way around the exposed outside edges.

The tricky part is where the concave edge meets at the break in the leading edge corner. This took the most work.

You won't be able to judge how well the rounded edges meet until you spray it with some filler/primer later on.

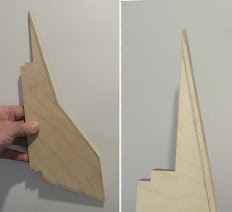

On the left,

is the first rough knock down of the right side trailing edge.

On the right is a good rounded edge on a different fin.

I wouldn't sand the blackened laser cut root edge until you check the fit before gluing the fins thru the wall and against the motor mount tube.

Looks nice! Typically I use a 1/4 or 1/8 rounding edge contour sanding block to keep it consistent .

ReplyDelete