I don't see why it's necessary. Years ago, sanding die-cut balsa might help free up a fin that wasn't cut all the way through the sheet.

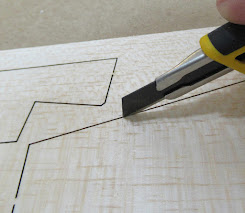

All you need is a knife blade to free the fins, cutting through the hold-down tics.

Never punch out laser cut fins without cutting through the tabs. I use a break-off blade to remove the fins. I save the more expensive X-Acto #11 blades for more delicate cuts.

As mentioned many times before,

Laser cuts diffuse and widen when burning through the balsa.

The bottom side of a laser cut is wider than the top. You can see line widths by flipping over a fin sheet. The laser cut is a wedge cut.

On the left is a before and after sanding of the slightly angled sides. The butt joint (right side) after sanding is much better.

More in the next post . . .

My experience with laser cut balsa parts doesn’t quite jive with Chris’s - especially parts from Estes. My GG’s fins were not cut all the way through consistently, it took some knife work to get some of the parts free. Still better than die “crushed” fins but it appears that the laser cutter Estes’ supplier uses isn’t quite hot enough to cut through the hardest spots in the balsa sheets. Not a big deal but something to be aware of.

ReplyDeleteHi Openroad,

DeleteThe complete laser cuts seem to vary from kit to kit. These Great Goblin fins were cut through the 1/8" thick balsa. The hold down tics required knife cuts from both sides to get through the dense balsa.