TIP: Along with glue on the flat edge, roll some glue on the inside so you will get an interior fillet.

Press the disks into the glue and turn the disk to even out the inside fillet.

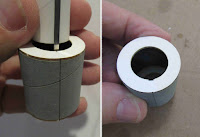

Before the glue sets up, roll the glued disk and coupler on a flat surface to even up the edges. I'm not sanding here, I'm just rolling the the coupler and disk on the flat side of the sanding block to even out the edges.

I was surprised there wasn't a laser cut notch for the engine hook.

TIP: Notice the line down the black coupler. Notches are cut on both disks, the pencil line helps keep both notches in line.

Here's the finished engine mount.

With 1" space at the bottom, the upper ring goes right over the upper bend of the engine hook. The Kevlar tied line loop went under that upper bend.

TIP: When Kevlar is tied under the hook, try to glue the centering over the upper bend of the hook - much stronger.

No comments:

Post a Comment