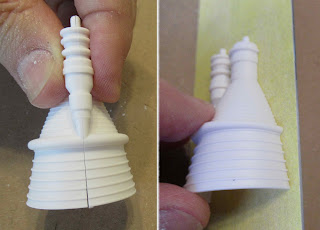

The nozzles have been improved with new molds. Only two pieces, a right and left side. No separate heat exchanger on the side that sometimes ended up being too short.

The halves fit together well but with an extra step you can make it better.

TIP: One side has pins on the edges, the other side has holes to fit those pin locations.

Lightly sand the holes side flattening it out. Don't sand the pin side.

Check the following two "bell" pictures before gluing -

I prefer liquid cement over tube style cement.

Brush glue on the top inside edges. You have to work quickly, the liquid glue dries fast.

While pressing the sides closed, you can dab some liquid cement onto the top pin areas.

Double check the large bell end.

There might be a little bit of "play" in the fit.

Move and line up the sides for the smoothest surface between the bands.

Brush some liquid cement down the inside joints.

Liquid cement almost disappears after it dries. If you don't over do it, it rarely shows up after paint is applied.

No comments:

Post a Comment